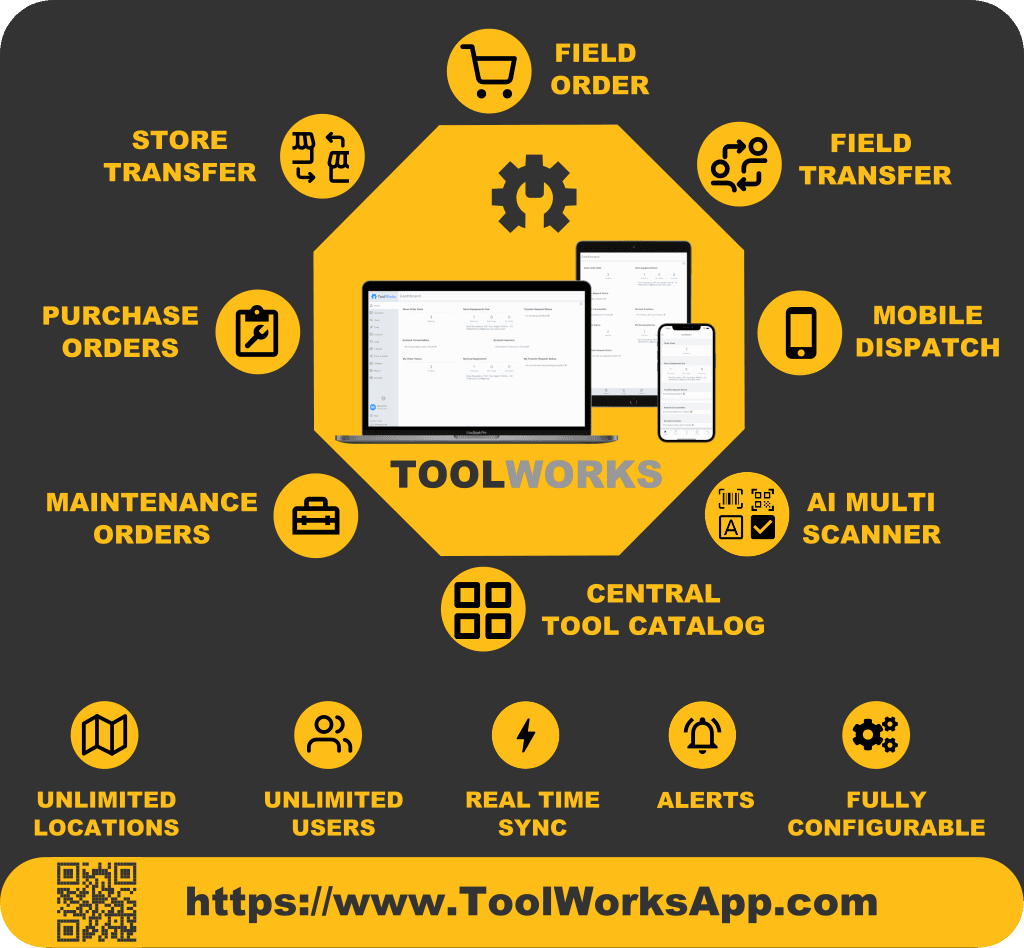

Best 7 Tool Tracking Software products

What is Tool Tracking Software?

Tool Tracking Software helps businesses keep tabs on their tools and equipment, making sure nothing gets lost or misplaced. It’s especially useful on job sites or in workshops where many tools are shared among workers.